A telehandler, sometimes called a telescopic handler (we’ve also heard them referred to as reach forklift, boom lift, and cherry picker), is a versatile powerhouse in the construc

A telehandler, sometimes called a telescopic handler (we’ve also heard them referred to as reach forklift, boom lift, and cherry picker), is a versatile powerhouse in the construction industry.

Marrying the capabilities of a forklift and a crane, it's designed to handle various tasks, from lifting heavy loads to reaching heights that typical machinery can't. Whether elevating pallets to tall buildings or precisely placing materials in tight spots, telehandlers are indispensable assets on construction sites.

Telehandler Dimensions and Sizes

When it comes to telehandlers, one size doesn't fit all. Telehandlers come in various dimensions and sizes, each tailored to serve specific needs within the construction industry. Remember that these classifications vary by company, region, and job site.

Often referred to as compact telehandlers, they typically have a maximum operating weight ranging from 5,500 to 11,000 pounds (2.75 to 5.5 tons). They are designed for operations in tighter spaces like urban construction sites or indoor projects.

These typically fall within a maximum operating weight range of about 11,000 to 22,000 pounds (5.5 to 11 tons). They offer a balance of maneuverability and lifting capacity, suitable for many tasks requiring more power than compact telehandlers but without the bulk of the larger models.

Large or heavy-duty (or high-capacity) telehandlers usually have a maximum operating weight exceeding 22,000 pounds (11 tons). These powerful machines are designed for the most demanding tasks, such as lifting heavy materials to significant heights or over considerable distances. Their size and strength make them ideal for large-scale construction projects, industrial applications, or any job site that requires the movement of heavy loads.

Telehandler Weights and Implications

These machines come in various weights tailored to specific requirements.

Manufacturers typically categorize telehandlers based on their weight, which correlates with their lifting capacity and size. For instance, a compact telehandler weighs much less than a heavy-duty or high-capacity model. This categorization helps potential users to gauge the machine's suitability for specific tasks quickly.

The weight of a telehandler has direct implications on its stability. When lifting loads, especially at full extension, the machine's weight is a counterbalance, making sure it remains grounded and stable. A lighter machine might be more susceptible to toppling or tipping when handling heavy materials, especially if extended far from the base. Therefore, operators must be mindful of the telehandler's weight, especially when working at maximum reach.

There’s a link between a telehandler's weight and maximum lifting capacity. A heftier machine typically has a larger engine, sturdier tires, and a comprehensive counterbalance system. These components collectively contribute to its ability to lift heavier loads safely. It's not just about the machine's weight but also how it is distributed and interacts with the mechanical systems in place.

The weight of a telehandler significantly influences its transportation logistics. Moving heavier models might require specialized trailers, and in certain regions, road weight restrictions may require transportation permits. You’ll need to be equipped to transport your telehandler safely and legally, which is crucial to avoid potential delays or penalties.

While looking at a telehandler's weight as just another spec on a sheet might be tempting, it plays a vital role in its performance, safety, and logistics. Whether renting, buying, or operating, a good understanding of this ensures optimal operation and can prevent costly or dangerous missteps.

Lifting Capacity: How Much Can a Telehandler Lift?

Lifting capacity is arguably one of the most looked-at specs of a telehandler. This metric determines how much weight the machine can safely lift and handle without jeopardizing stability or operational efficiency.

A telehandler's lifting capacity reflects its design, engineering, and build quality. This capacity denotes the maximum weight the machine can handle under specified conditions. However, this doesn't mean a telehandler can always lift its maximum capacity under all circumstances. Environmental factors, the machine's angle, and attachment type can all influence the real-world lifting limit.

As previously discussed, the weight of a telehandler impacts its stability. A heavier telehandler with a well-distributed weight is often better positioned to lift heavier loads, especially when the machine's counterbalance mechanisms come into play.

Outriggers are extendable legs that can be deployed to enhance the stability of a telehandler. They distribute the weight of the machine and its load over a larger area, preventing tipping and providing a more stable lifting platform. When using a telehandler to lift near its maximum capacity or extend its reach significantly, deploying outriggers is often recommended, if not essential. The ground beneath the outriggers needs to be firm and stable to provide adequate support.

But that’s not all outriggers do. They also help level a telehandler. SANY telehandlers, for example, can help level by +/- 10°.

The length and angle at which the boom is extended play pivotal roles in determining the lifting capacity. Generally, the further the boom is extended, especially at steeper angles, the lower the safe lifting capacity becomes. Both extending the boom and adjusting its angle can shift the machine's center of gravity, thus affecting stability. It's essential to understand that the interplay of height, angle, and load determines the telehandler's overall operational safety and capability.

Different attachments can influence the lifting capacity. A bucket might allow for different weight distributions compared to a fork attachment. It's crucial to refer to the machine's load charts when switching attachments to ensure safe operation.

The stability of the ground where the telehandler operates is crucial. Due to potential stability concerns, soft, uneven, or slippery terrains can reduce the machine's effective lifting capacity.

Operating a telehandler on an incline, known as the grade, can significantly affect the machine's capability under load. The grade, combined with the degree which the boom is lifted, has a compounded effect on the telehandler's center of mass. These angles play together, altering the center of gravity substantially. Even with the outriggers deployed, the combination of grade and boom angle can change the thresholds at which the machine is considered stable. That's why leveling is super important; while outriggers help with stability, they have their limits. It's always recommended to operate the telehandler on level ground when handling heavy loads to ensure maximum stability and safety.

The hydraulic system powers the telehandler's lifting mechanisms. A more powerful system can handle heavier weights, but it should be used with other safety measures for stability.

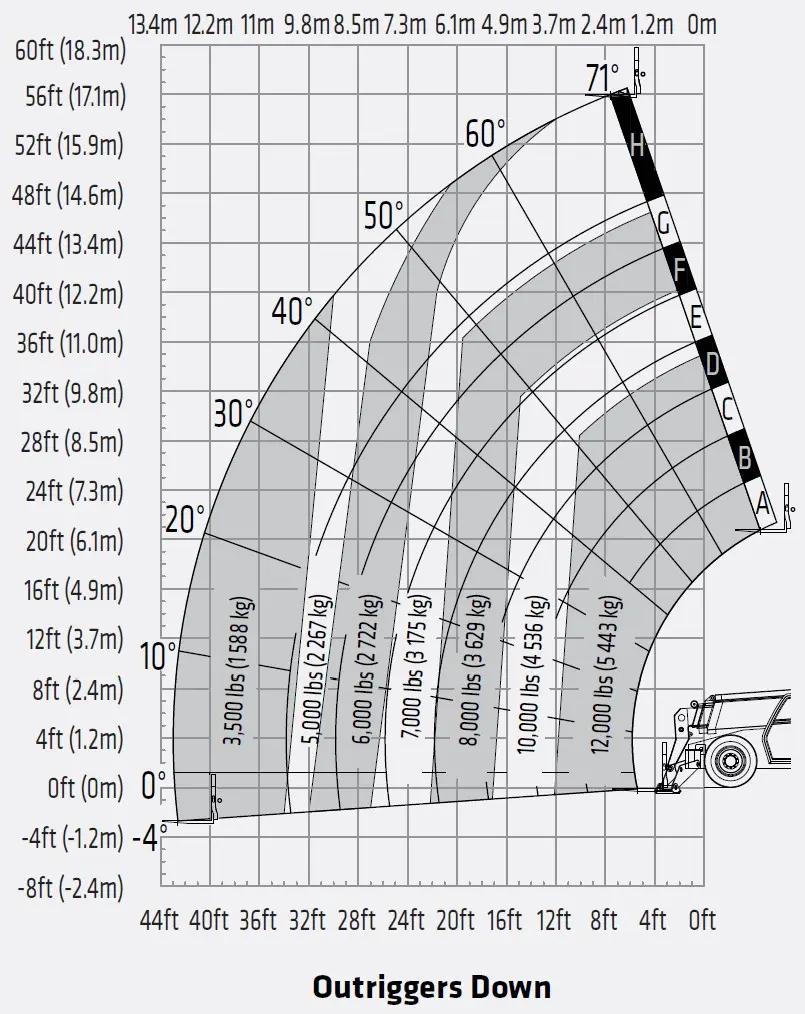

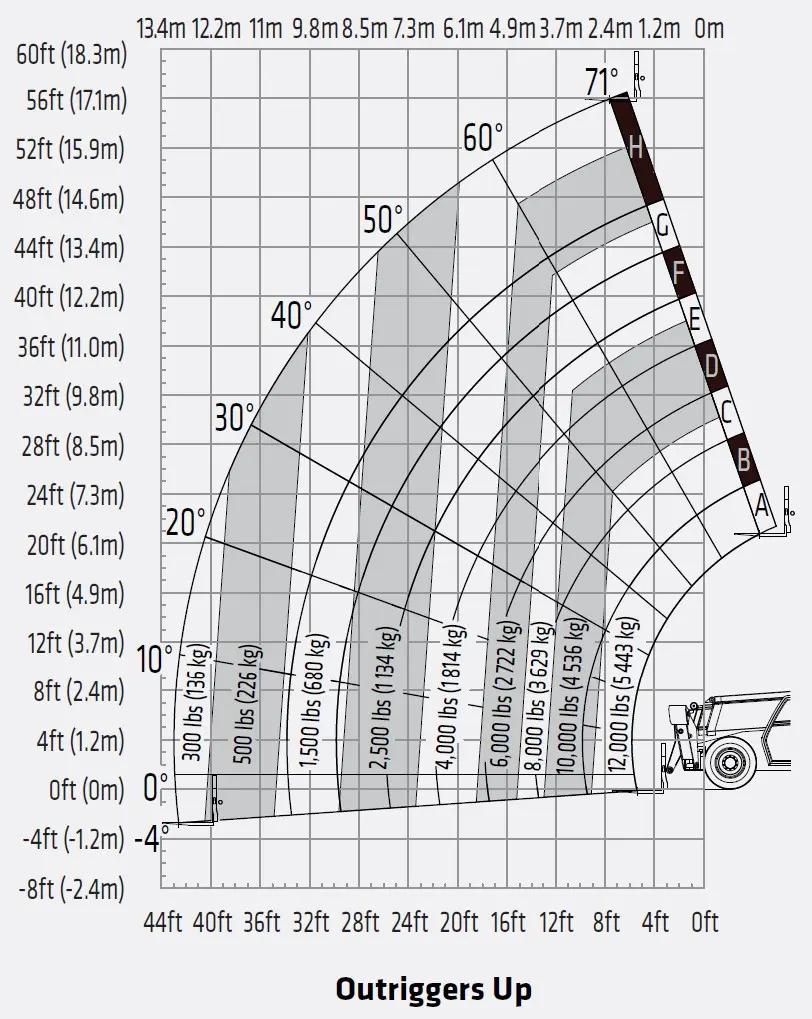

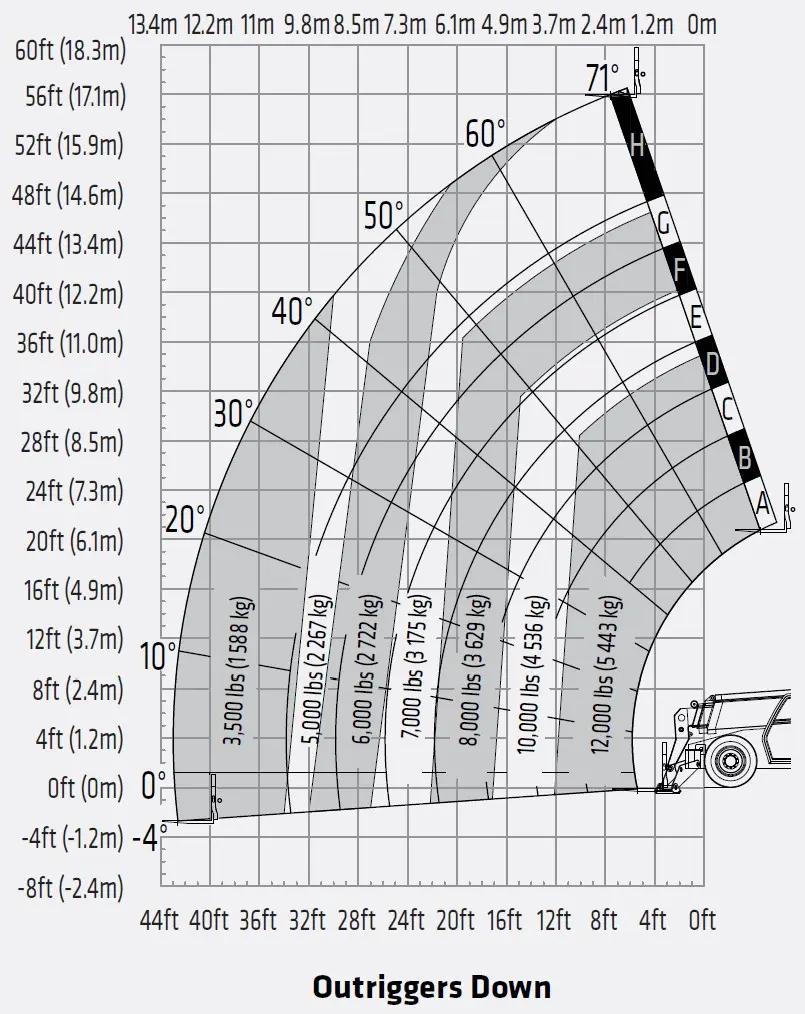

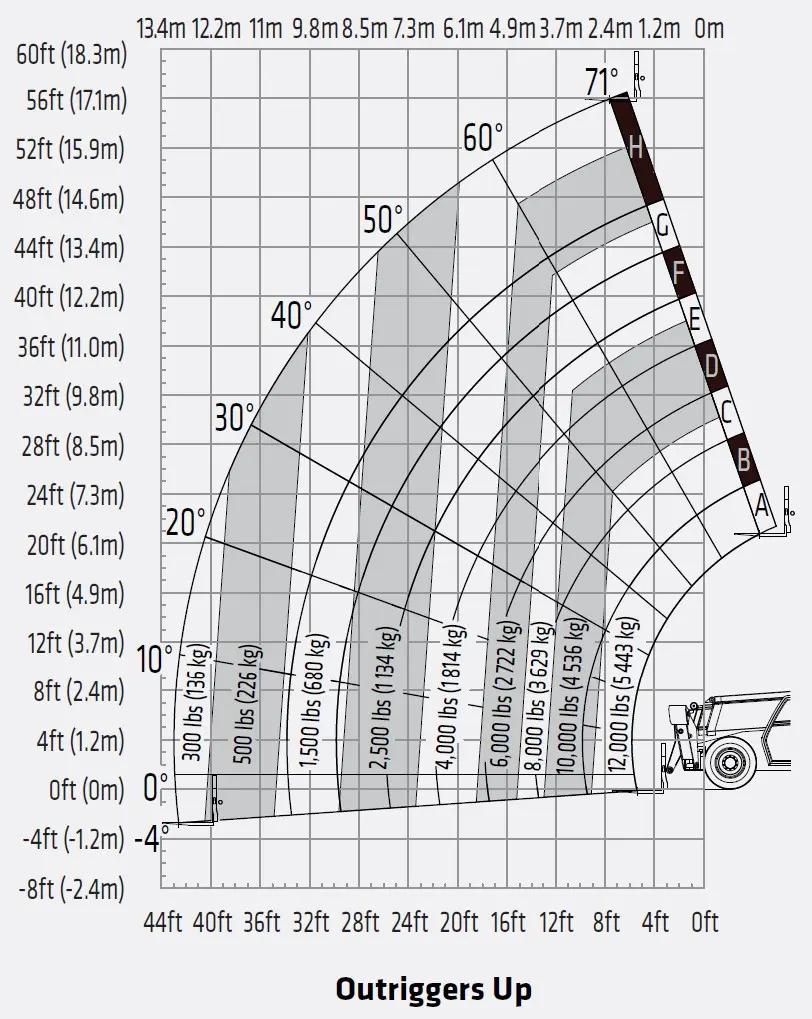

Telehandler Load Chart

A telehandler load chart is a vital tool for operators, providing essential data that’s important for safe and efficient machine operation. Not just a mere table of numbers; it's a comprehensive guide that offers insights into the machine's capabilities and limitations under various conditions.

Load charts are unique to each telehandler model and are often provided by the manufacturer. They depict the safe lifting capacities of the machine at different boom lengths and angles. It's not just about how much weight the machine can lift but under what specific circumstances. Misunderstanding or disregarding the load chart can lead to hazardous situations, including tip-overs or mechanical failures.

Telehandler Specs to Consider

Understanding its specifications is important whether you're in the market to buy, rent, or simply operate a telehandler. These specs provide insights into the machine's capabilities, helping you choose the right equipment for the job and operate it safely. Here's a breakdown of the key telehandler specs to consider:

What it is: The total weight of the telehandler when it's operational, including fluids and typical attachments.

Why it's important: The operating weight can affect transportation needs, ground pressure, and overall machine stability.

What it is: The maximum weight the telehandler can safely lift.

Why it's important: This defines the scale of tasks the machine can handle and ensures safe operation without overloading.

What it is: The maximum height to which the telehandler can lift a load.

Why it's important: It determines the reach of tasks the machine can undertake, especially in vertical spaces.

What it is: The maximum distance the telehandler can extend its boom horizontally.

Why it's important: This spec is crucial for tasks that require reaching over obstacles or working at a distance from the machine's base.

What it is: The output of the telehandler's engine, typically measured in horsepower or kilowatts.

Why it's important: Engine power can influence the machine's performance, speed, and efficiency, especially under heavy loads.

What it is: The kind and dimensions of the tires equipped on the telehandler.

Why it's important: Tires play a role in machine stability, terrain adaptability, and overall operational efficiency.

What it is: The distance between the base of the telehandler and the ground.

Why it's important: Ground clearance can influence the machine's ability to operate on uneven terrains or over obstacles.

What it is: The amount of fuel the machine's tank can hold.

Why it's important: This spec can give insights into the operational duration of the telehandler before refueling is needed.

What it is: The capacity and capabilities of the machine's hydraulic system.

Why it's important: It dictates the machine's lifting efficiency and can influence the operation of hydraulic-powered attachments.

In conclusion, these specifications serve as a roadmap to the capabilities and limits of a telehandler. Always match the specs to the job requirements when considering a purchase or rental. Doing so ensures optimal performance, safety, and return on investment.

Conclusion

Telehandlers are some of the most versatile and valuable pieces of machinery in construction and related industries. Grasping the nuances of their sizes, weights, and lifting capacities isn't just a technical drill but a fundamental step toward optimizing their use.

Whether you're considering adding a telehandler to your fleet or renting one for a specific project, diving into the specs is crucial. It ensures not only the safety and efficiency of your operations but also the longevity and performance of the machine. So, before you seal the deal on your next telehandler, check to see if you've got all its specs down pat. Your projects—and your peace of mind—will thank you.

Popular Telehandlers and Their Specs

Telehandler spec sources:

GehlGenie LiftJLGManitouSkyjackSkytrakXtreme

A telehandler, sometimes called a telescopic handler (we’ve also heard them referred to as reach forklift, boom lift, and cherry picker), is a versatile powerhouse in the construction industry.

Marrying the capabilities of a forklift and a crane, it's designed to handle various tasks, from lifting heavy loads to reaching heights that typical machinery can't. Whether elevating pallets to tall buildings or precisely placing materials in tight spots, telehandlers are indispensable assets on construction sites.

Telehandler Dimensions and Sizes

When it comes to telehandlers, one size doesn't fit all. Telehandlers come in various dimensions and sizes, each tailored to serve specific needs within the construction industry. Remember that these classifications vary by company, region, and job site.

Often referred to as compact telehandlers, they typically have a maximum operating weight ranging from 5,500 to 11,000 pounds (2.75 to 5.5 tons). They are designed for operations in tighter spaces like urban construction sites or indoor projects.

These typically fall within a maximum operating weight range of about 11,000 to 22,000 pounds (5.5 to 11 tons). They offer a balance of maneuverability and lifting capacity, suitable for many tasks requiring more power than compact telehandlers but without the bulk of the larger models.

Large or heavy-duty (or high-capacity) telehandlers usually have a maximum operating weight exceeding 22,000 pounds (11 tons). These powerful machines are designed for the most demanding tasks, such as lifting heavy materials to significant heights or over considerable distances. Their size and strength make them ideal for large-scale construction projects, industrial applications, or any job site that requires the movement of heavy loads.

Telehandler Weights and Implications

These machines come in various weights tailored to specific requirements.

Manufacturers typically categorize telehandlers based on their weight, which correlates with their lifting capacity and size. For instance, a compact telehandler weighs much less than a heavy-duty or high-capacity model. This categorization helps potential users to gauge the machine's suitability for specific tasks quickly.

The weight of a telehandler has direct implications on its stability. When lifting loads, especially at full extension, the machine's weight is a counterbalance, making sure it remains grounded and stable. A lighter machine might be more susceptible to toppling or tipping when handling heavy materials, especially if extended far from the base. Therefore, operators must be mindful of the telehandler's weight, especially when working at maximum reach.

There’s a link between a telehandler's weight and maximum lifting capacity. A heftier machine typically has a larger engine, sturdier tires, and a comprehensive counterbalance system. These components collectively contribute to its ability to lift heavier loads safely. It's not just about the machine's weight but also how it is distributed and interacts with the mechanical systems in place.

The weight of a telehandler significantly influences its transportation logistics. Moving heavier models might require specialized trailers, and in certain regions, road weight restrictions may require transportation permits. You’ll need to be equipped to transport your telehandler safely and legally, which is crucial to avoid potential delays or penalties.

While looking at a telehandler's weight as just another spec on a sheet might be tempting, it plays a vital role in its performance, safety, and logistics. Whether renting, buying, or operating, a good understanding of this ensures optimal operation and can prevent costly or dangerous missteps.

Lifting Capacity: How Much Can a Telehandler Lift?

Lifting capacity is arguably one of the most looked-at specs of a telehandler. This metric determines how much weight the machine can safely lift and handle without jeopardizing stability or operational efficiency.

A telehandler's lifting capacity reflects its design, engineering, and build quality. This capacity denotes the maximum weight the machine can handle under specified conditions. However, this doesn't mean a telehandler can always lift its maximum capacity under all circumstances. Environmental factors, the machine's angle, and attachment type can all influence the real-world lifting limit.

As previously discussed, the weight of a telehandler impacts its stability. A heavier telehandler with a well-distributed weight is often better positioned to lift heavier loads, especially when the machine's counterbalance mechanisms come into play.

Outriggers are extendable legs that can be deployed to enhance the stability of a telehandler. They distribute the weight of the machine and its load over a larger area, preventing tipping and providing a more stable lifting platform. When using a telehandler to lift near its maximum capacity or extend its reach significantly, deploying outriggers is often recommended, if not essential. The ground beneath the outriggers needs to be firm and stable to provide adequate support.

But that’s not all outriggers do. They also help level a telehandler. SANY telehandlers, for example, can help level by +/- 10°.

The length and angle at which the boom is extended play pivotal roles in determining the lifting capacity. Generally, the further the boom is extended, especially at steeper angles, the lower the safe lifting capacity becomes. Both extending the boom and adjusting its angle can shift the machine's center of gravity, thus affecting stability. It's essential to understand that the interplay of height, angle, and load determines the telehandler's overall operational safety and capability.

Different attachments can influence the lifting capacity. A bucket might allow for different weight distributions compared to a fork attachment. It's crucial to refer to the machine's load charts when switching attachments to ensure safe operation.

The stability of the ground where the telehandler operates is crucial. Due to potential stability concerns, soft, uneven, or slippery terrains can reduce the machine's effective lifting capacity.

Operating a telehandler on an incline, known as the grade, can significantly affect the machine's capability under load. The grade, combined with the degree which the boom is lifted, has a compounded effect on the telehandler's center of mass. These angles play together, altering the center of gravity substantially. Even with the outriggers deployed, the combination of grade and boom angle can change the thresholds at which the machine is considered stable. That's why leveling is super important; while outriggers help with stability, they have their limits. It's always recommended to operate the telehandler on level ground when handling heavy loads to ensure maximum stability and safety.

The hydraulic system powers the telehandler's lifting mechanisms. A more powerful system can handle heavier weights, but it should be used with other safety measures for stability.

Telehandler Load Chart

A telehandler load chart is a vital tool for operators, providing essential data that’s important for safe and efficient machine operation. Not just a mere table of numbers; it's a comprehensive guide that offers insights into the machine's capabilities and limitations under various conditions.

Load charts are unique to each telehandler model and are often provided by the manufacturer. They depict the safe lifting capacities of the machine at different boom lengths and angles. It's not just about how much weight the machine can lift but under what specific circumstances. Misunderstanding or disregarding the load chart can lead to hazardous situations, including tip-overs or mechanical failures.

Telehandler Specs to Consider

Understanding its specifications is important whether you're in the market to buy, rent, or simply operate a telehandler. These specs provide insights into the machine's capabilities, helping you choose the right equipment for the job and operate it safely. Here's a breakdown of the key telehandler specs to consider:

What it is: The total weight of the telehandler when it's operational, including fluids and typical attachments.

Why it's important: The operating weight can affect transportation needs, ground pressure, and overall machine stability.

What it is: The maximum weight the telehandler can safely lift.

Why it's important: This defines the scale of tasks the machine can handle and ensures safe operation without overloading.

What it is: The maximum height to which the telehandler can lift a load.

Why it's important: It determines the reach of tasks the machine can undertake, especially in vertical spaces.

What it is: The maximum distance the telehandler can extend its boom horizontally.

Why it's important: This spec is crucial for tasks that require reaching over obstacles or working at a distance from the machine's base.

What it is: The output of the telehandler's engine, typically measured in horsepower or kilowatts.

Why it's important: Engine power can influence the machine's performance, speed, and efficiency, especially under heavy loads.

What it is: The kind and dimensions of the tires equipped on the telehandler.

Why it's important: Tires play a role in machine stability, terrain adaptability, and overall operational efficiency.

What it is: The distance between the base of the telehandler and the ground.

Why it's important: Ground clearance can influence the machine's ability to operate on uneven terrains or over obstacles.

What it is: The amount of fuel the machine's tank can hold.

Why it's important: This spec can give insights into the operational duration of the telehandler before refueling is needed.

What it is: The capacity and capabilities of the machine's hydraulic system.

Why it's important: It dictates the machine's lifting efficiency and can influence the operation of hydraulic-powered attachments.

In conclusion, these specifications serve as a roadmap to the capabilities and limits of a telehandler. Always match the specs to the job requirements when considering a purchase or rental. Doing so ensures optimal performance, safety, and return on investment.

Conclusion

Telehandlers are some of the most versatile and valuable pieces of machinery in construction and related industries. Grasping the nuances of their sizes, weights, and lifting capacities isn't just a technical drill but a fundamental step toward optimizing their use.

Whether you're considering adding a telehandler to your fleet or renting one for a specific project, diving into the specs is crucial. It ensures not only the safety and efficiency of your operations but also the longevity and performance of the machine. So, before you seal the deal on your next telehandler, check to see if you've got all its specs down pat. Your projects—and your peace of mind—will thank you.

Popular Telehandlers and Their Specs

Telehandler spec sources:

GehlGenie LiftJLGManitouSkyjackSkytrakXtreme